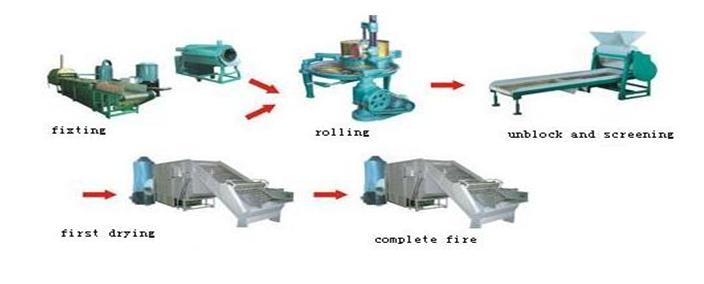

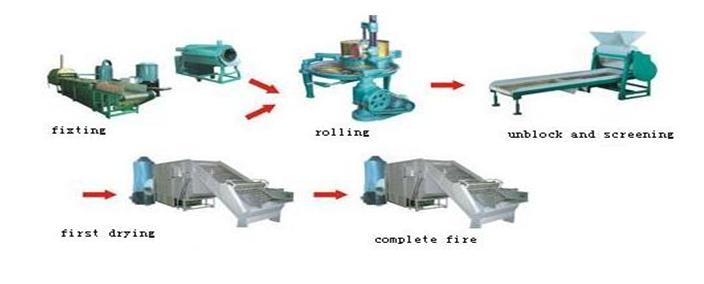

The complete Green tea

production line Processing

Procedure

Process:

1

Fresh tea leaves to dry tea to

tea fannings

1)This

is the first step called fixing.

2)This is the second step called

fixing.

3)This is the third step called

roasting

4)This is the fourth step called

smashing. This machine can make

your tea become powder. We

called it green tea powder.

2

Filling, heat sealing ,threading

,labeling,and over wrapping

1)This is the fivth step called

packing, involve the filling,

heat sealing ,threading

,labeling, and over wrapping.

Threading need the thread,

Labeling need the tag, over

wrapping need the envelop

material and adhesive.

2)this is the sixth step called

over-wrapping.this step need the

cellophane

Fixing Machine

Technical Data:

|

Part No |

Main power

|

Output per hour

|

outsize (L×W×H)

(mm) |

|

6TCST-30 |

11.81kw |

20-35kg/h |

1855×485×1180 |

|

6TCST-40 |

19.09kw |

55-80kg/h |

2205×700×1400 |

|

6TCSZ-40 |

0.59kw |

40-50kg/h |

2205×700×1400 |

|

6TCST-60 |

1.3kw |

150-180kg/h |

4180×980×2190 |

|

6TCST-70 |

3.15kw |

200-250kg/h |

5070×1100×2620 |

|

6TCST-80 |

3.5kw |

250-300kg/h |

4600×1100×3500 |

|

6TCZS-50 |

5.48kw |

30-60kg/h |

5700×560×1350 |

|

6TCZS-150

|

10.07kw |

80-150kg/h

|

6920×810×1600 |

|

6TCZS-300 |

12.37kw |

150-300kg/h |

|

Drying Machine

Technical Data

|

Model |

Outsize

(LxWxH)(mm) |

Output

(kg/h) |

Main power

(kw) |

|

6TCHB-3.0 |

3100×840×1400 |

10-20 |

1.6 |

|

6TCHB-6.0 |

4853×1524×1650 |

≥25 |

0.75 |

|

6TCHB-10 |

5760×1530×1650 |

40-60 |

0.75 |

|

6TCHB-16 |

6380×1530×2000 |

≥30 |

1.1 |

|

6TCHB-20 |

6710×1780×2100 |

≥35 |

1.1 |

|

6TCH-30 |

6400×2120×2400 |

160-180 |

10.1 |

|

CTN6CHB-3.0 |

3100X840X1400 |

≥12 |

0.8kw |

Rolling Machine

Technical Data

|

Model |

Main power |

Output

(kg/h) |

Outsize

(LxWxH)(mm) |

Pulverizer

Technical Data

|

Model |

Capacity

Kg/h |

Main shaft speed

Rpm |

Pulverizing Fineness

Mesh |

Motor Power

Kw |

Machine Weight

Kg |

Outsize

(LxWxH) (mm) |

|

T180 |

75-100 |

4200 |

50-150 |

2.2 |

70 |

500x420x1250 |

|

T250 |

100-250 |

4200 |

50-150 |

5.5 |

180 |

650x600x1350 |

|

T320 |

250-300 |

4200 |

50-150 |

7.5 |

250 |

750x700x1450 |

|

T350 |

200-550 |

4200 |

50-150 |

11 |

400 |

850x800x1650 |

|

T400 |

300-800 |

4200 |

50-150 |

15 |

700 |

1050x1000x2 |

Tea bag machine

Technical Data

|

Part NO. |

English name |

Functions |

|

CCFD6 |

Tea bag machine |

Out-inner bag are

finished directly at the

same time. |

|

DXDC8Ⅰ |

Tea bag machine |

No outside envelop, the

tea bags are put in the

box directly. |

|

DXDC8Ⅱ |

Tea bag machine |

Out-inner bag are

finished directly at the

same time. |

|

DXDC8IV |

Tea bag machine |

Out-inner bag are

finished directly at the

same time. |

|

DXDC15 |

Tea bag machine |

Out-inner bag are

finished directly at the

same time. |

| |

Auto-boxing device

AB01 |

|

| |

Date printing

equipment-01

DP01 |

|

| |

Stirrer

ST01 |

|

| |

Output-counter

OC01 |

|

Over-wrapping machine

Technical Data

|

Part NO. |

English Name

|

Unit

|

Functions |

|

BT-110 |

Over Wrapping Machine |

PC

|

one mould will be free

with the machine |

|

BT-400C-I |

Over Wrapping Machine |

PC

|

one mould will be free

with the machine |

|

BT-250A |

Over Wrapping Machine |

PC

|

one mould will be free

with the machine |

|

BT-2000B |

Over Wrapping Machine |

PC

|

one mould will be free

with the machine |

|

BT-2000A |

Over Wrapping Machine |

PC

|

one mould will be free

with the machine |

|

BT350-A |

Over Wrapping Machine |

PC |

one mould will be free

with the machine |

| |

Mould For BT-350A |

PC |

Define |

| |

Printing Device |

PC |

Define |

Materials